The Importance of Supply Chain Visibility and Defect Tracking

Posted on: November 28th 2024

In today’s complex global supply chain, 79% of organizations’ revenue growth is accelerated by high-performing supply networks, surpassing the industry average. Meanwhile, only 6% of companies have whole supply chain visibility, which leaves a sizable gap in their capacity to oversee and manage operations.

The blog explores the critical role of Supply Chain Visibility (SCV) in maximizing operational efficiency, managing risks, and meeting market demands. It highlights how SCV enables businesses to track products end-to-end and proactively optimize each stage, from manufacturing to delivery. Read on.

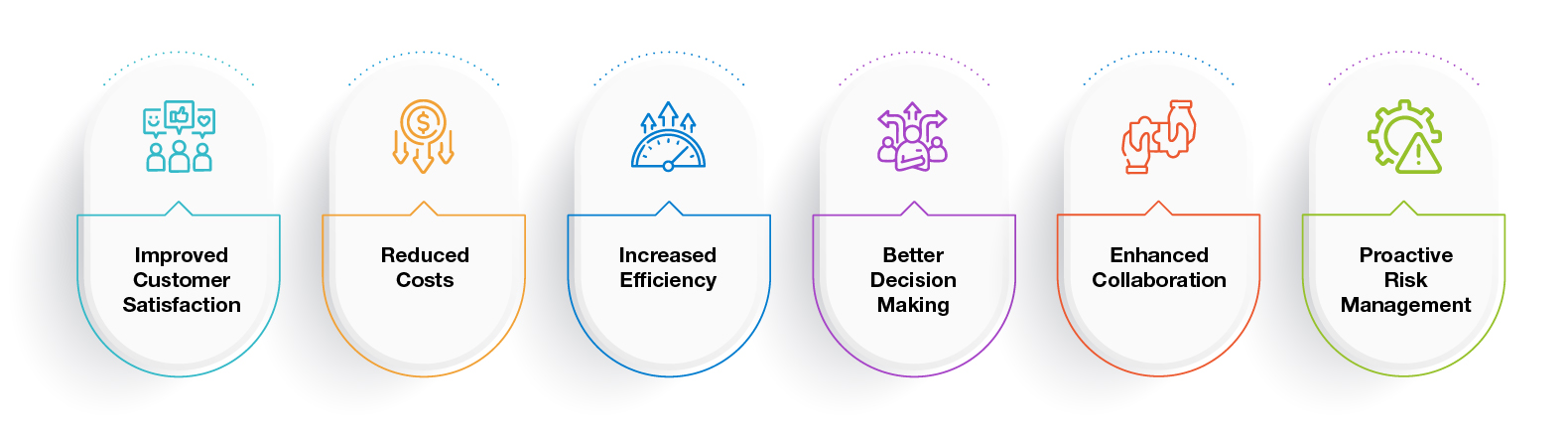

The Benefits of Supply Chain Visibility

Supply chain visibility brings several significant benefits to businesses, enhancing their operational effectiveness and overall competitiveness. Key advantages include:

Improved Customer Satisfaction

By implementing real-time tracking of goods and services, businesses can ensure that customers receive high-quality products on time, every time. This transparency allows organizations to convey order statuses proactively, fostering customer loyalty and trust, which builds customer loyalty and trust. Keeping customers updated on their orders throughout the supply chain process increases the likelihood that they will feel appreciated and satisfied with their experience.

Reduced Costs

Supply chain visibility enables businesses to identify and rectify operational inefficiencies. Organizations can reduce waste and minimize delays by clearly understanding their processes. This proactive approach leads to lower operational costs, ultimately increasing profitability. For example, companies can avoid unnecessary expenditures associated with excess stock or expedited shipping by optimizing inventory levels and streamlining logistics.

Increased Efficiency

Real-time visibility into supply chain operations allows businesses to streamline their processes effectively. With accurate inventory levels and shipment status data, organizations can reduce unnecessary waste and ensure that resources are utilized efficiently. This optimization enhances productivity and contributes to faster turnaround times for orders, improving the overall flow of goods through the supply chain.

Better Decision Making

Access to supply chain visibility data equips businesses with the insights needed for informed decision-making. Organizations can quickly adapt their strategies in response to market changes or disruptions by analyzing trends and performance metrics in real-time. This agility enables companies to remain competitive and responsive in a dynamic business environment, ensuring they can effectively meet customer demands.

Enhanced Collaboration

Supply chain visibility offers a single platform for information sharing, which promotes improved stakeholder engagement. With this enhanced communication, suppliers, manufacturers, and logistics providers may make well-informed decisions based on real-time data. Enhanced communication leads to quicker problem resolution and more efficient resource use across the supply chain.

Proactive Risk Management

Businesses with thorough supply chain visibility can spot possible dangers before they become serious problems. Businesses can predict disruptions from supplier insolvency or regulatory changes by tracking key performance indicators and examining data trends. By taking a proactive approach to risk management, operational effects are lessened, and service delivery is maintained.

The Reputational Risk of Supply Chain Invisibility

Supply chain invisibility can severely hamper an organization’s reputation. A study by Rouvia found that 70% of consumers are likely to move to a rival after encountering a problem with the supply chain. A betrayal of confidence can damage a brand’s reputation and client loyalty. Businesses that maintain insufficient records or a transparent supply chain run the risk of regulatory sanctions. In industries with limited visibility, such as food and pharmaceuticals, serious fines for breaking safety laws can result in lost sales and harm a company’s reputation.

The Human Cost of Supply Chain Disruptions

Disruptions in the supply chain may force workers to work longer hours, contributing to stress and burnout. According to a recent survey by the Society for Human Resource Management, 31% of U.S. workers said that their occupations have a detrimental effect on their mental health, with many of them reporting feelings of overwhelm and anxiety as a result of work-related stress. This increased stress may impact the general morale and productivity of the workforce.

The Economic Consequences of Limited Visibility

Supply chain transparency issues can cause firms to incur large long-term expenditures beyond short-term financial losses. According to a report by ParkourSC, billions of dollars worth of products are lost annually due to unresolved blind spot-related supply chain problems. The paper highlights the economic impact of these inefficiencies by revealing that product spoiling from limited visibility costs the pharmaceutical, food, and beverage sectors USD 358 million yearly.

Conclusion

In today’s business environment, where competition is the order of the day, achieving visibility and efficient defect monitoring across the supply chain becomes necessary for businesses that seek to enhance operational effectiveness, lower costs, or improve customer service levels. In that condition, businesses can utilize the latest technologies, such as AI, IoT, and data analytics. Today’s tools to manage their supply chains effectively can be anticipated, and processes can be streamlined.

Enhanced visibility improves operational efficiency in the short run, helps build customer loyalty, and enhances brand equity and sustainability in the long run. On the other hand, the factors causing the invisibility of the supply chain have very detrimental effects on the whole, affecting such things as employees and financial status.

In the face of such dynamics, businesses must embrace transparency and deploy technologies that allow operational insight into supply chains. This will enable businesses to satisfy the market’s present needs and be ready for any other changes while carrying out their activities.

About the Author

Sanjeev Kumar Jain/Sanjeev Jain is an experienced technology writer. He brings a wealth of experience and knowledge to his writing through his keen interest in data, AI, and analytics. Sanjeev is an avid reader with a particular interest in business, aviation, politics, and emerging technologies.

We want to hear from you

Leave a Message

Our solutioning team is eager to know about your

challenge and how we can help.