From Automation to Autonomy: The Future of AI in Supply Chains

Posted on : November 18th 2024

Did you know that AI can boost supply chain efficiency by up to 20% and cut costs by 15%?

As AI reshapes the industry, manual processes are replaced by predictive and real-time decision-making capabilities, such as demand forecasting and route optimization.

According to Gartner, 75% of companies are expected to adopt AI-powered supply chains by 2025. This marks a shift towards data-driven decisions that provide enhanced visibility and operational optimization across the supply chain. This blog discusses how AI is changing the future of the supply chain.

| Read our blog to learn how AI and machine learning revolutionize supply chain operations. |

AI Today: Beyond the Basics

The current state of supply chain management AI applications is changing quickly, demonstrating the technology’s immense disruptive potential. Businesses increasingly use AI to improve decision-making processes, streamline operations, and increase efficiency across various supply chain functions. AI transforms supply chain procedures and empowers companies to meet customer requests better. Examples of these practices include dynamic routing, inventory optimization, and predictive demand forecasting.

| Predictive Demand Forecasting: By accurately predicting demand, companies can minimize inventory costs, avoid overstocking, and make informed supply chain decisions. This approach improves customer satisfaction by reducing out-of-stock situations and delays. |

| Dynamic Routing: AI systems optimize travel routes by considering fuel prices, weather, and traffic patterns. Through real-time optimization, businesses can reduce transportation costs and expedite delivery times. |

| Inventory Optimization: By analyzing historical sales data, weather patterns, and other factors, machine learning algorithms can generate accurate demand forecasts. This enables companies to hold the right amount of inventory at the right time, reduce the risk of over or understocking, and help businesses minimize waste, reduce inventory costs, and improve supply chain efficiency. |

| Warehouse Management: AI algorithms analyze data from sensors, cameras, and RFID tags to track inventory levels, monitor warehouse conditions, and predict potential issues. This enables real-time decision-making and improved efficiency. With AI, warehouse managers can automate inventory counting, order picking, and shipping tasks, reducing labor costs and increasing accuracy. |

| Customer Service: Generative AI-powered chatbots and virtual assistants transform supply chain customer service. They efficiently handle inquiries, order tracking, updates, and issue resolution. These systems improve over time using natural language processing and machine learning, enhancing the customer experience. |

Emerging Trends in AI Algorithms

As AI becomes increasingly integral to supply chain autonomy, several emerging trends are set to redefine its application and impact. Three developments offer every imaginable possibility: Cognitive Collaboration, Quantum-Inspired Computing, and Swarm Intelligence. These sophisticated developments allow businesses to forecast demand, identify potential disruptions, and optimize logistics with unimaginable accuracy.

| Discover the transformative benefits of AI in supply chains with our blog. |

A. Cognitive Collaboration

Cognitive collaboration revolutionizes the supply chain landscape by enabling end-to-end coordination between all stakeholders and allowing seamless communication and coordination. This involves integrating human expertise and AI-driven insights to create a unified decision-making process. According to Stargo Co, cognitive supply chains are characterized by the ability to “connect the dots” between operators, shippers, and retailers, allowing for real-time visibility and control over the entire supply chain. This collaborative approach enables companies to respond quickly to changes in demand, optimize inventory levels, and reduce costs.

B. Quantum-Inspired Computing

Quantum-inspired computing transforms the supply chain landscape by enabling companies to optimize complex logistics operations quickly and accurately. According to an article in the online publishing platform Medium.com, quantum-inspired computing revolutionizes supply chain logistics by solving previously unsolvable problems. By analyzing real-time data, quantum-inspired computing can help optimize routes, reduce fuel consumption, and lower emissions. This technology can also help companies predict and prevent disruptions, such as traffic congestion and weather events, allowing them to respond quickly and effectively to changing conditions.

C. Swarm Intelligence

Swarm intelligence involves the coordination of multiple autonomous agents, such as drones or robots, to achieve a common goal. Swarm intelligence can be applied in supply chains to optimize logistics and transportation. Walmart uses swarm AI to optimize inventory allocation across stores, reducing stockouts and improving product availability. Target leverages edge computing to collect real-time product inventory and customer behavior data, improving store operations and personalizing the shopping experience. Amazon leverages AI and automation, including swarm intelligence, to optimize warehouse robots and delivery routes, leading supply chain innovation.

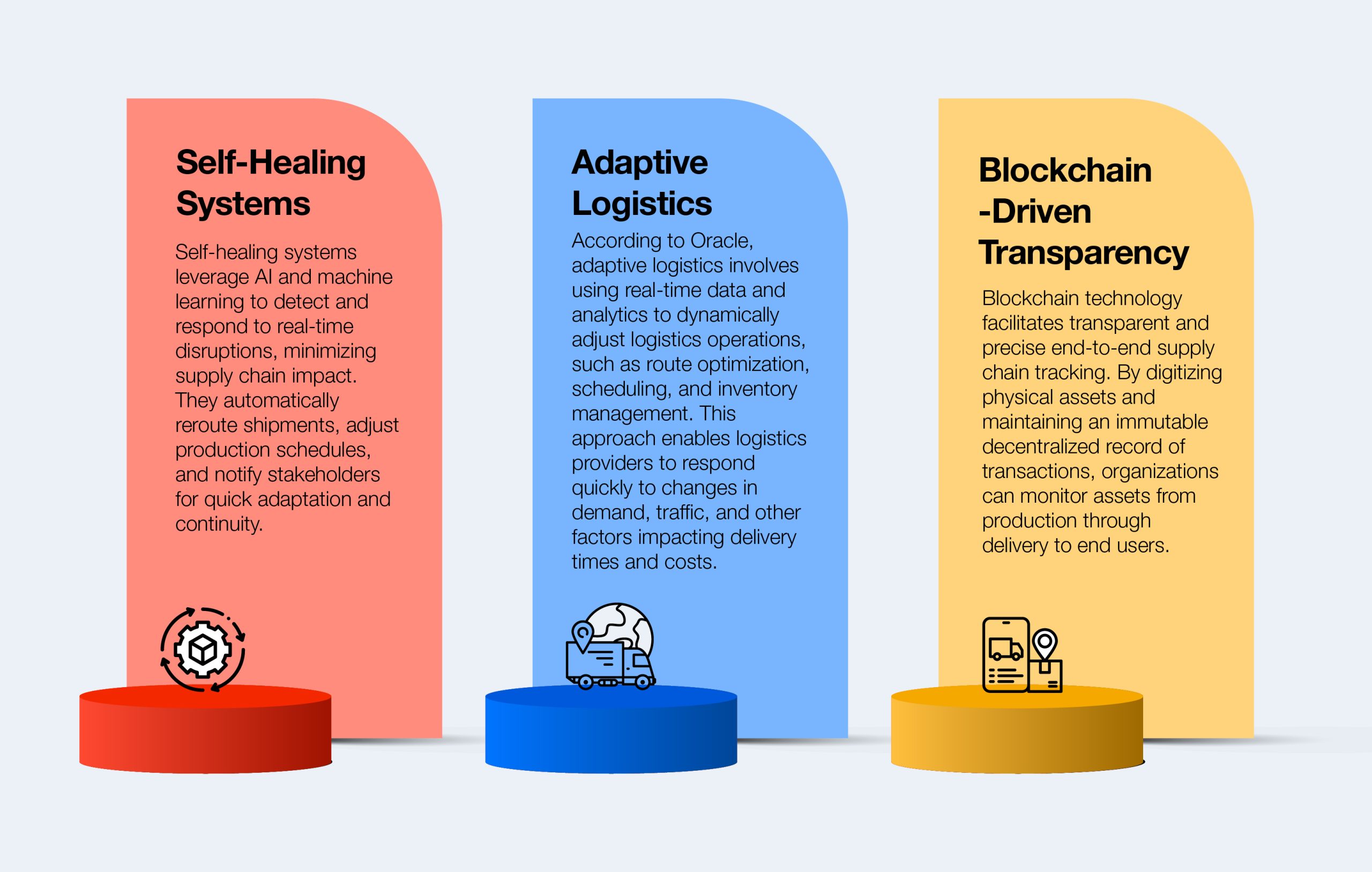

Autonomous Supply Chains

In the future, AI, blockchain, and IoT will revolutionize supply chains. Logistics routes will adapt in real-time, systems will autonomously handle issues, and transactions will be transparently monitored. Forward-thinking businesses are already embracing these technologies.

| Learn how AI-driven demand forecasting can optimize inventory levels and streamline supply chain processes with our blog |

As supply chains become autonomous, they must address fairness, job displacement, and transparency. Prioritizing these challenges will help create an equitable and efficient future.

Human-AI Symbiosis

In the evolving landscape of AI in supply chains, it must be understood that AI complements human decision-making rather than replacing it. AI efficiently processes large data volumes, identifying patterns and trends. However, humans play a crucial role in interpreting these insights and making informed choices. AI is a supportive tool, not a replacement for human judgment.

AI optimizes logistics routes and schedules, freeing humans for higher-value tasks. AI systems identify disruptions and improve forecasting. Rather than fearing job displacement, we should collaborate with AI to enhance efficiency, reduce costs, and improve customer satisfaction.

Beyond Profit and Toward Sustainability

Today companies are looking for ways to reduce their environmental impact and promote social responsibility. Artificial intelligence (AI) plays a vital role in this effort, helping companies achieve sustainable supply chains that benefit both the planet and their bottom line.

Circular Economy: AI can significantly enhance the circular economy by helping companies create sustainable supply chains. As noted by McKinsey, AI enables the analysis of data related to product usage, recycling, and waste, facilitating the design of more efficient systems. It can predict demand to minimize waste and optimize logistics to reduce emissions, promoting sustainable growth through reduced waste and resource conservation.

Eco-optimized Routes: AI can also help optimize routes and reduce the environmental impact of supply chain operations. By analyzing traffic patterns, weather, and other factors, generative AI can predict the most efficient shipment routes, reducing fuel consumption and emissions. For example, EY notes in its report that a leading logistics company used generative AI to optimize its routes, resulting in a 15% reduction in fuel consumption and a 12% reduction in emissions. Additionally, AI can help companies identify opportunities to consolidate shipments and reduce the number of vehicles on the road, reducing their environmental impact.

How Straive Can Help

Straive offers a complete package of AI-driven solutions designed to transform supply chain management across the complete logistics flow:

1. Demand and Capacity Planning: Straive’s advanced demand forecasting tools use time series analysis and capacity simulation to align resources and prevent supply-demand mismatches, achieving over 95% forecast accuracy.

2. AI-Powered Warehouse Optimization: With smart task allocation and real-time data integration, Straive’s solutions improve warehouse traffic management, reducing facility turn times by up to 16% and minimizing detention fees.

3. Fleet and Transportation Efficiency: Straive’s AI-based fleet management and route optimization systems enhance operational efficiency, providing actionable insights to reduce transportation costs and improve fleet safety.

4. Data-Driven Decision-Making: Through intelligent data extraction and analysis, Straive empowers organizations to streamline manual processes, ensuring compliance, accuracy, and faster operational workflows, such as 100% customs compliance through automated audit checks.

With logistics and supply chain management expertise, we support end-to-end transformation by integrating AI with tailored solutions that deliver cost savings, improve efficiency, and ensure sustainable, future-ready supply chains.

About the Author

Sanjeev Kumar Jain/Sanjeev Jain is an experienced technology writer. He brings a wealth of experience and knowledge to his writing through his keen interest in data, AI, and analytics. Sanjeev is an avid reader with a particular interest in business, aviation, politics, and emerging technologies.

We want to hear from you

Leave a Message

Our solutioning team is eager to know about your

challenge and how we can help.