A Trifecta of Supply Chain Gains with Digital Twins

Posted on : September 13th 2024

Author : Sudhakaran Jampala

An Epochal Transition

McKinsey analysis indicates that the global market for digital-twin technology will grow by 60 percent annually to reach $73.5 billion by 2027, with the supply chain sector playing a significant role.

Digital twins, virtual representations of real-life objects or systems, are detailed enough to enable predictive analysis and real-time decision-making, driving agility in supply chain systems.

These digital models offer real-time visualization of operations, from goods in transit to inventories, allowing companies to instantly assess disruptions or risks. Supply chains, influenced by variables like market fluctuations, geopolitical changes, consumer preferences (e.g., ESG considerations), require adaptable systems to manage these complexities.

The COVID-19 pandemic was a stark reminder of the need for supply chain resilience, forcing enterprises to retool and prepare for future disruptions.

What follows is an analysis of the top three reasons why supply chains need digital twins.

Reason 1: The Power of Comprehensive Visibility

Digital twins provide real-time end-to-end visibility across supply chains, enabling quick detection of issues and timely responses. This level of transparency allows companies to make fact-based decisions, reduce inefficiencies and cut costs.

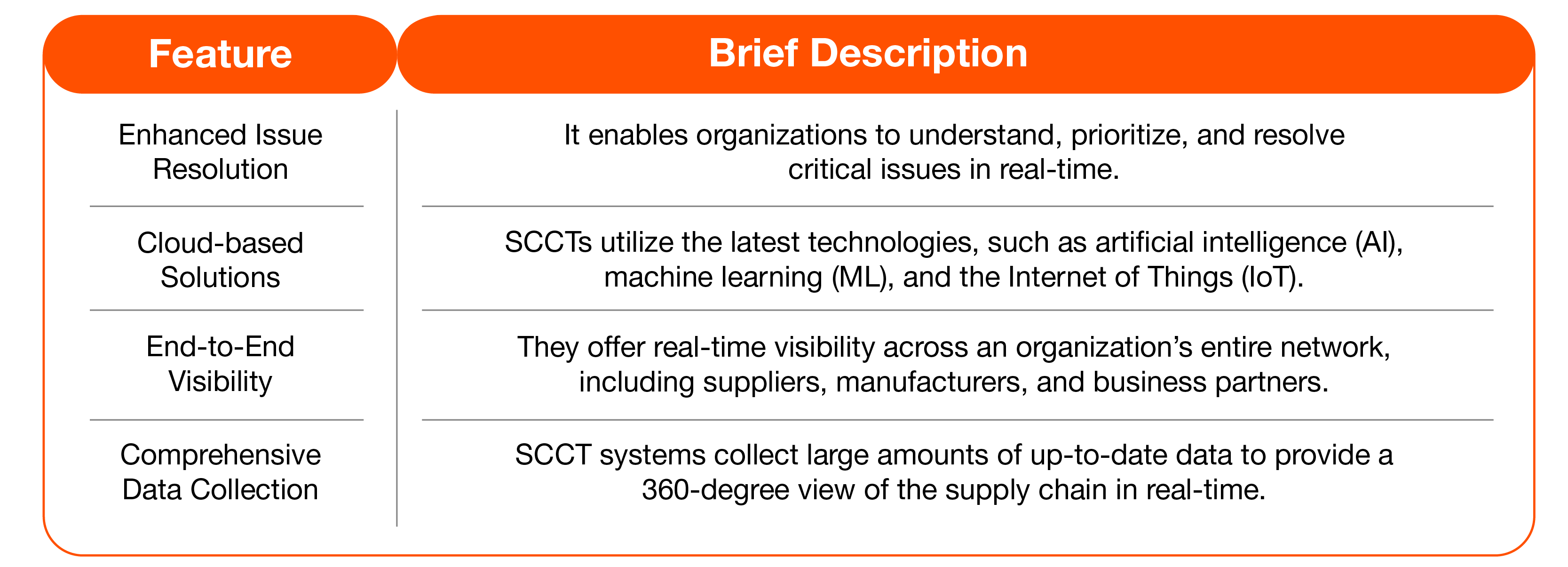

A Supply Chain Control Tower (SCCT) acts as a centralized hub that provides real-time insights and predictive analytics across the entire supply chain. Leveraging data from IoT sensors, ERP platforms, and transportation management systems (TMS), SCCTs enable scenario modeling, what-if analyses, and quick issue resolution. IBM describes SCCTs as personalized dashboards of key business metrics, offering enhanced communication and collaboration across supply chain partners.

Source: IBM, Straive Research

With these capabilities, SCCTs support dynamic planning and routing, enabling businesses to respond efficiently to supply chain disruptions.

Reason 2: Enhanced Operational Efficiencies

Digital twins streamline complex operations, allowing for seamless stakeholders integration and cost reduction. By predicting disruptions, they enable interventions like smart alerts and real-time insights, fostering supply chain resiliency. AI-powered tools can spot and address anomalous events dynamically, ensuring prompt responses to unforeseen challenges.

Emerging technologies like advanced analytics and generative AI enhance and scenario predictions. Tailored to a company’s unique needs, digital twins leverage AI to optimize operations in complex environments, transforming supply chain management from reactive to proactive.

In today’s intricate supply chain ecosystem, driven by globalization, and rising customer expectations, digital twins empower organizations to navigate complexities with data-driven tools like vision analytics, ensuring efficient management across processes and systems.

Reason 3: Risk Alleviation

Digital twins are pivotal in risk management, offering real-time data analysis and proactive monitoring. By combining both external and internal data, they provide companies with an edge in anticipating risks and mitigating potential disruptions.

Handling unstructured data, traditionally labor-intensive, is now feasible at scale with AI and ML tools. These technologies process large volumes of alternative and unstructured data, delivering a 360-degree view of supply chain risks. Digital twins use AI/ML automation to transform this data into actionable insights, ensuring robust risk management systems.

This platform-led approach allows companies to process massive amounts of data, assess risk signals in real time, and implement intelligent risk mitigation strategies.

Ensuring a 21st Century Supply Chain with Digital Twins

The demand for real-time analytics is growing as businesses strive to adapt swiftly to changing conditions and seize emerging opportunities. Predictive modeling is also gaining traction, allowing companies to anticipate future trends and make proactive decisions.

Overall, digital twins empower businesses to optimize operations, enhance decision-making, and improve risk management across supply chains – meeting the demands of today’s complex global landscape.

How Straive Helps

Our wide spectrum of AI services leverages machine learning algorithms to identify patterns and perform cognitive functions such as natural language processing and image/visual recognition.

We help drive supply chain applications across diverse industries, from virtual assistants to simulations to autonomous decision-making.

We want to hear from you

Leave a Message

Our solutioning team is eager to know about your

challenge and how we can help.